Follow the Kia Picanto Scheduled maintenance service if the vehicle is usually operated where none of the following conditions apply. If any of the following conditions apply, follow the Maintenance Under Severe Usage Conditions.

Why a Maintenance Schedule is Important?

- It eliminates unexpected replacements and breakdowns.

- It keeps costs down because repairs are not made on an emergency basis.

- It extends the lives of expensive common elements and reduces reserved funds

- It stops problems before they occur

What is included in Kia Picanto maintenance?

- Every 3,000 to 7,000 Miles. The majority of mechanics still suggest that the oil and oil filter be replaced between 3,000 and 7,000 miles. This is the time to also have the transmission fluid, coolant, power steering fluid, windshield washer fluid and wipers, tires and all exterior lights checked.

- Every 15,000 to 20,000 miles. Replace the air filter. Also have the battery and coolant inspected.

- Every 25,000 miles. Replace the fuel filter.

- Every 30,000 miles. Replace the air filter and power steering fluid and have the coolant, radiator hoses, HVAC system, brake pads, and all suspension components checked and replaced as wanted.

- Every 35,000 miles. Check and replace the battery if it is not holding a charge or if it is three to four years old.

- Every 40,000 miles. Replace the spark plugs and spark plug wires, and check the ignition system and suspension.

- Every 60,000 miles. Replace brake pads and fluid, radiator hoses, coolant, power steering fluid, and timing belt. Check the HVAC, suspension components and tires.

Do I have to go to the dealership for regularly scheduled maintenance?

If you’re unsure about any servicing or maintenance procedure, have the system serviced by a professional workshop. Kia recommends to visit an authorised Kia dealer/service partner.

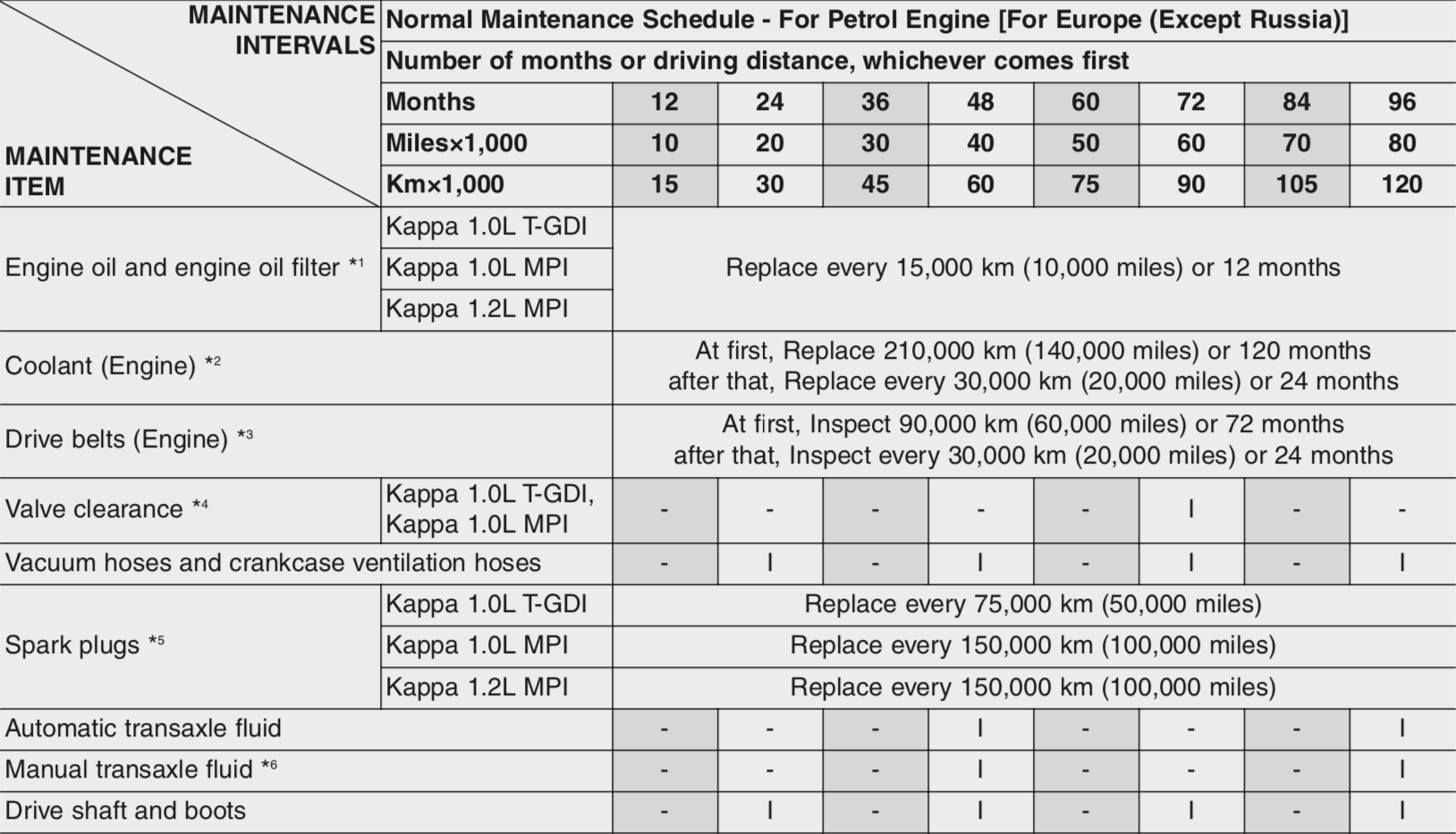

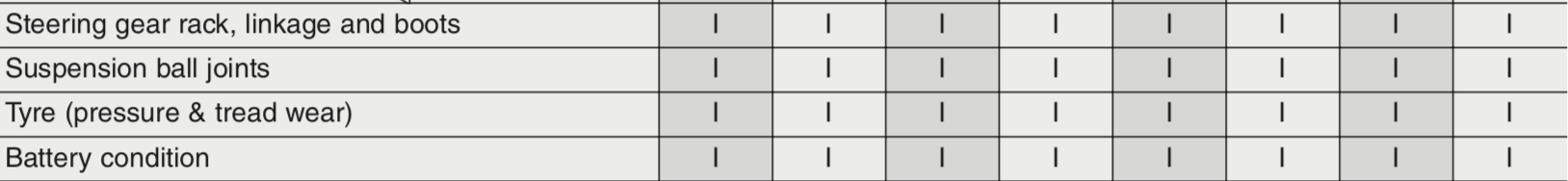

Normal Maintenance Schedule – For Petrol Engine [For Europe (Except Russia)]

The following maintenance services must be performed to ensure good emission control and performance. Keep receipts for all vehicle emission services to protect your warranty. Where both mileage and time are shown, the frequency of service is determined by whichever occurs first.

[table id=14 /]

I : Inspect and if necessary, adjust, correct, clean or replace. R : Replace or change.

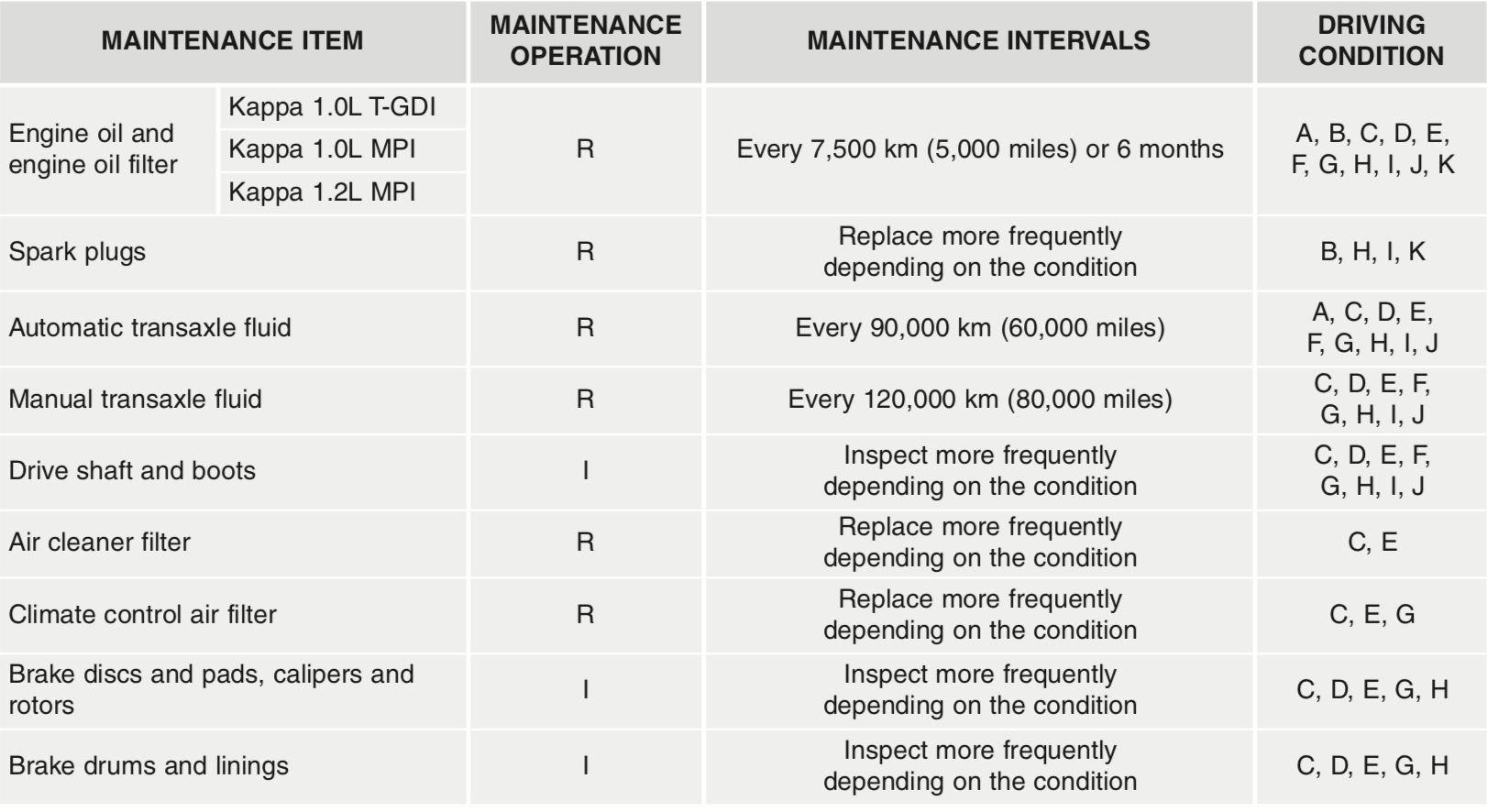

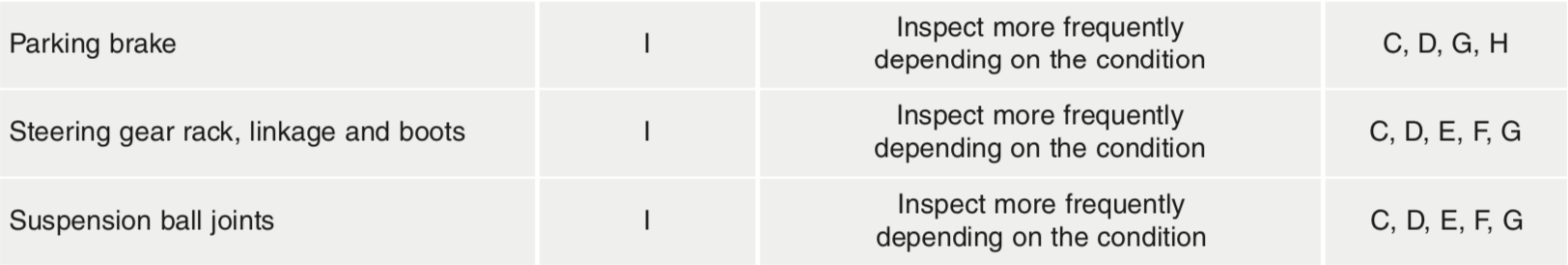

Maintenance Under Severe Usage Conditions – For Petrol Engine [For Europe (Except Russia)]

Maintenance operation

I : Inspect and if necessary, adjust, correct, clean or replace. R : Replace or change.

SEVERE DRIVING CONDITIONS

A: Repeatedly driving short distance of less than 8 km (5miles) in normal temperature or less than 16 km (10 miles) in freezing temperature.

B : Extensive engine idling or low speed driving for long dis- tances.

C : Driving on rough, dusty, muddy, unpaved, graveled or salt- spread roads.

D : Driving in areas using salt or other corrosive materials or in very cold weather

E : Driving in heavy dust condition

F : Driving in the heavy traffic area

G : Driving on uphill, downhill or mountain road repeatedly

H : Towing a trailer or using a camper on roof rack

I : Driving for patrol car, taxi, other commercial use of vehicle towing

J : Driving over 170km/h (106mile/h)

K: Frequently driving in stop-and-go conditions

Explanation of scheduled maintenance items

Engine oil and filter

The engine oil and filter should be changed at the intervals specified in the maintenance schedule. If the vehicle is being driven in severe con- ditions, more frequent oil and filter changes are required.

Drive belts

Inspect all drive belts for evidence of cuts, cracks, excessive wear or oil saturation and replace if necessary. Drive belts should be checked peri- odically for proper tension and adjusted as necessary.

Fuel filter (for petrol)

Kia petrol vehicle is equipped a lifetime fuel filter that integrated with the fuel tank. Regular maintenance or replacement is not needed but depends on fuel quality. If there are some important safety matters like fuel flow restriction, surging, loss of power, hard starting problem etc, fuel filter inspection or replace is needed. Have the fuel filter inspected or replaced by a professional workshop. Kia recommends to visit an authorised Kia dealer/service partner.

Fuel lines, fuel hoses and connections

Check the fuel lines, fuel hoses and connections for leakage and dam- age. Have the fuel lines, fuel hoses and connections replaced by a professional workshop. Kia recommends to visit an authorised Kia dealer/service partner.

Vapour hose (for Petrol, FFV engine) and fuel filler cap

The vapour hose and fuel filler cap should be inspected at those inter- vals specified in the maintenance schedule. Make sure that a new vapour hose or fuel filler cap is correctly replaced.

Vacuum crankcase ventilation hoses (if equipped)

Inspect the surface of hoses for evi- dence of heat and/or mechanical damage. Hard and brittle rubber, cracking, tears, cuts, abrasions, and excessive swelling indicate deterioration. Particular attention should be paid to examine those hose surfaces nearest to high heat sources, such as the exhaust manifold.

Inspect the hose routing to assure that the hoses do not come in contact with any heat source, sharp edges or moving component which might cause heat damage or mechanical wear. Inspect all hose connections, such as clamps and couplings, to make sure they are secure, and that no leaks are present. Hoses should be replaced immediately if there is any evidence of deterioration or damage.

Air cleaner filter

Have the air cleaner filter replaced by a professional workshop. Kia recommends to visit an authorised Kia dealer/service partner.

Spark plugs (for Petrol, FFV engine)

Make sure to install new spark plugs of the correct heat range.

Valve clearance (for Kappa 1.0L T-GDI, Kappa 1.0L MPI, FFV engine)

Inspect for excessive valve noise and/or engine vibration and adjust if necessary. In this case, have the system serviced by a professional workshop. Kia recommends to visit an authorised Kia dealer/service partner.

Cooling system

Check the cooling system components, such as the radiator, coolant reservoir, hoses and connections for leakage and damage. Replace any damaged parts.

Coolant

The coolant should be changed at the intervals specified in the maintenance schedule.

Manual transaxle fluid (if equipped)

Inspect the manual transaxle fluid according to the maintenance schedule.

Automatic transaxle fluid (if equipped)

The fluid level should be in the “HOT” range of the dipstick, after the engine and transaxle are at normal operating temperature. Check the automatic transaxle fluid level with the engine running and the transaxle in neutral, with the parking brake properly applied.

Brake hoses and lines

Visually check for proper installation, chafing, cracks, deterioration and any leakage. Replace any deteriorated or damaged parts immediately.

Brake/Clutch fluid (if equipped)

Check the brake/clutch fluid level in the brake/clutch fluid reservoir. The level should be between “MIN” and “MAX” marks on the side of the reservoir. Use only hydraulic brake/clutch fluid conforming to DOT 3 or DOT 4 specification.

Parking brake

Inspect the parking brake system including the parking brake lever (or pedal) and cables.

Brake discs, pads, calipers and rotors

Check the pads for excessive wear, discs for run out and wear, and calipers for fluid leakage.

Suspension mounting bolts

Check the suspension connections for looseness or damage. Retighten to the specified torque.

Steering gear box, linkage & boots/lower arm ball joint

With the vehicle stopped and engine off, check for excessive free-play in the steering wheel. Check the linkage for bends or damage. Check the dust boots and ball joints for deterioration, cracks, or damage. Replace any damaged parts.

Drive shafts and boots

Check the drive shafts, boots and clamps for cracks, deterioration, or damage. Replace any damaged parts and, if necessary, repack the grease.

Air conditioning refrigerant (if equipped)

Check the air conditioning lines and connections for leakage and damage.